-

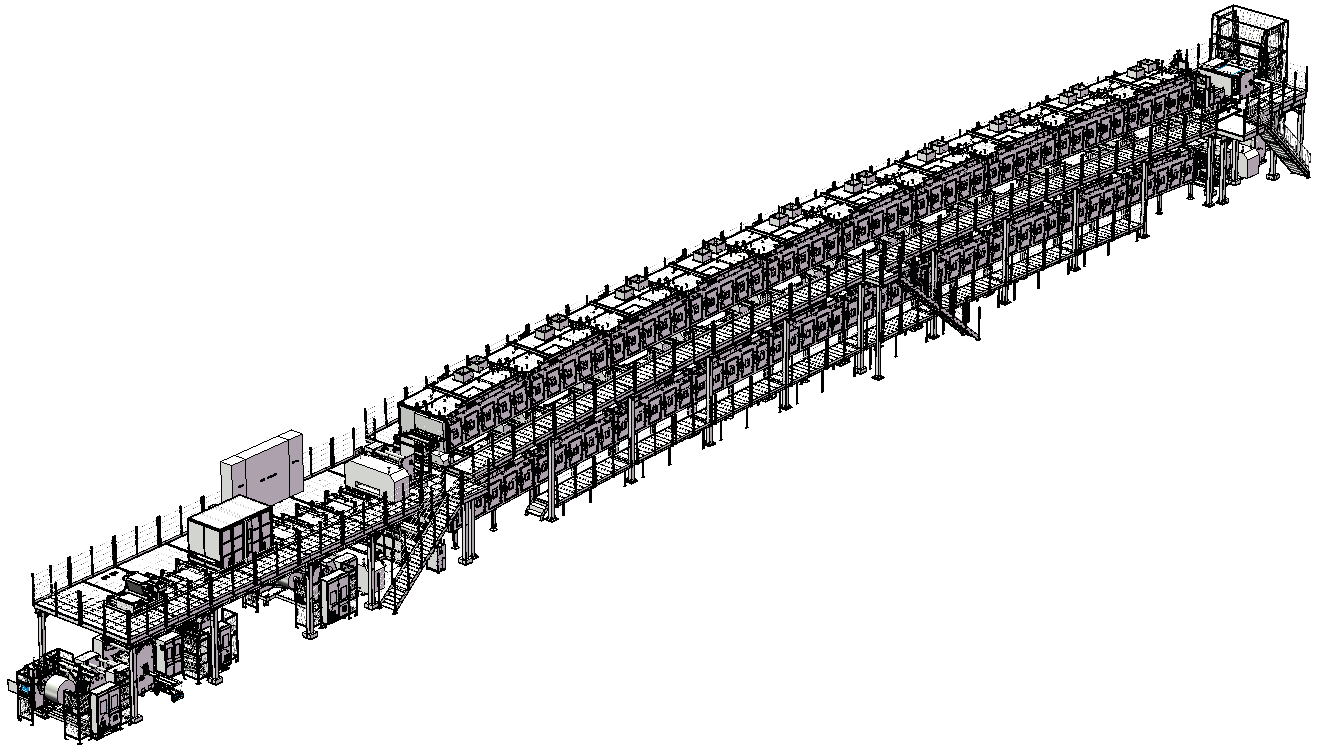

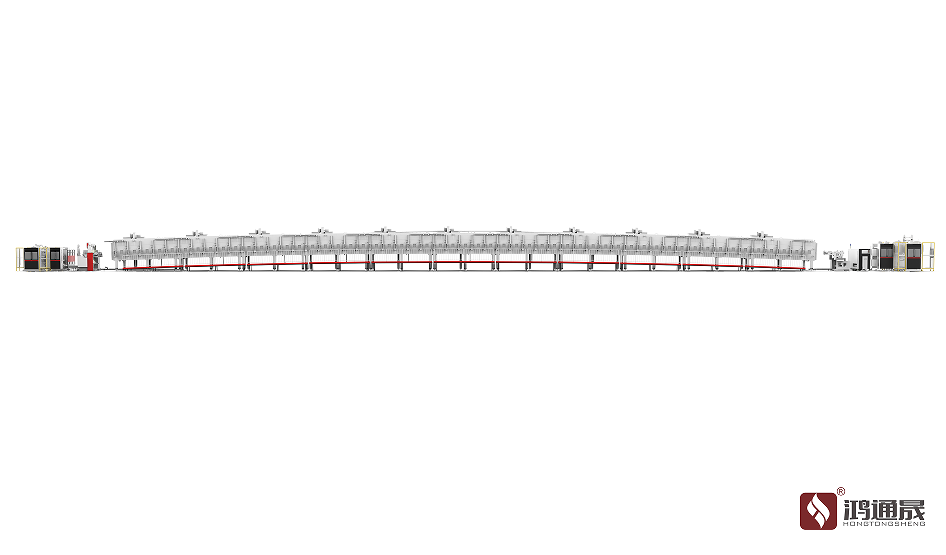

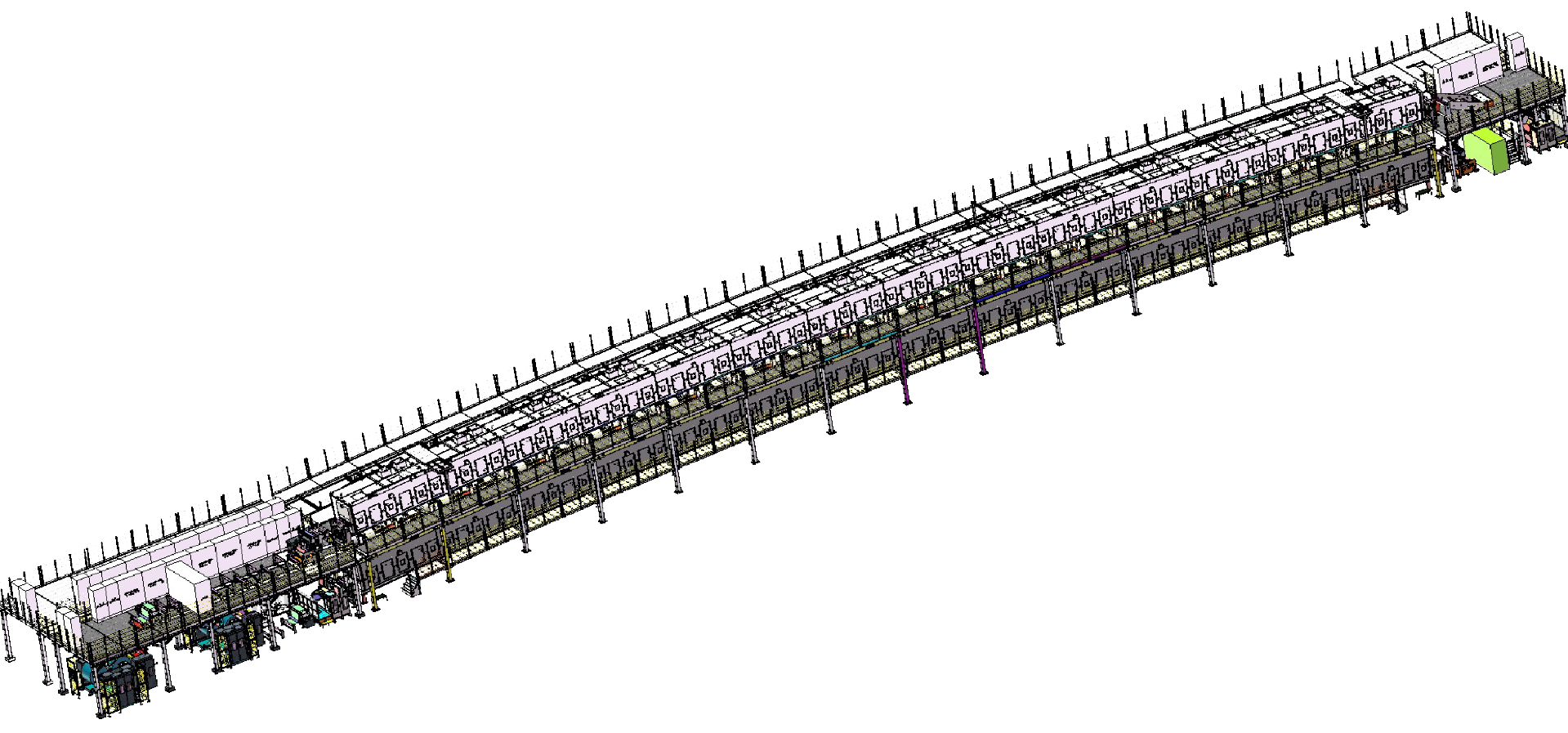

Double layer high-speed extrusion coating machine

-

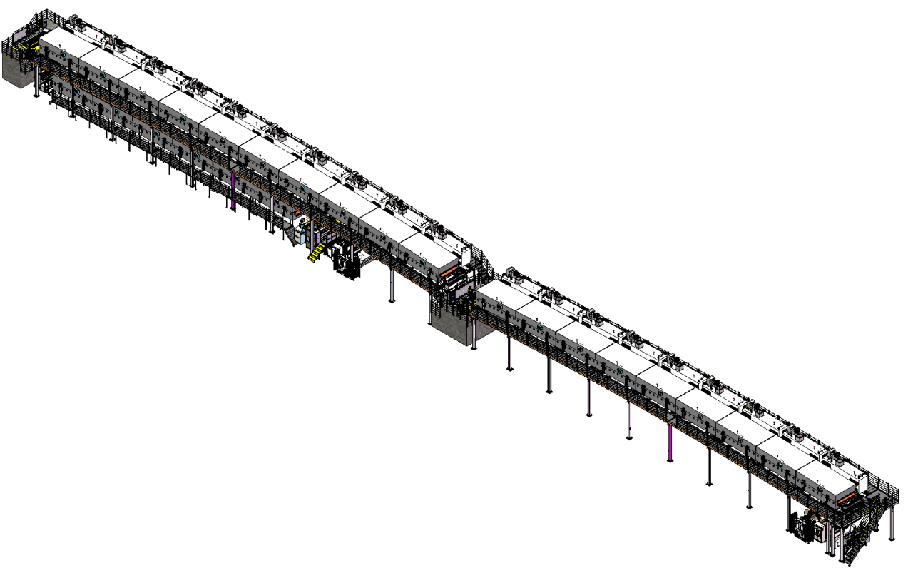

Coating and slitting integrated machine

-

Single layer extrusion coating machine

-

Double layer gravure bottom coating machine

-

Laboratory coating machine

-

Dry film making machine

-

Slitting machine

-

Perovskite coating machine

-

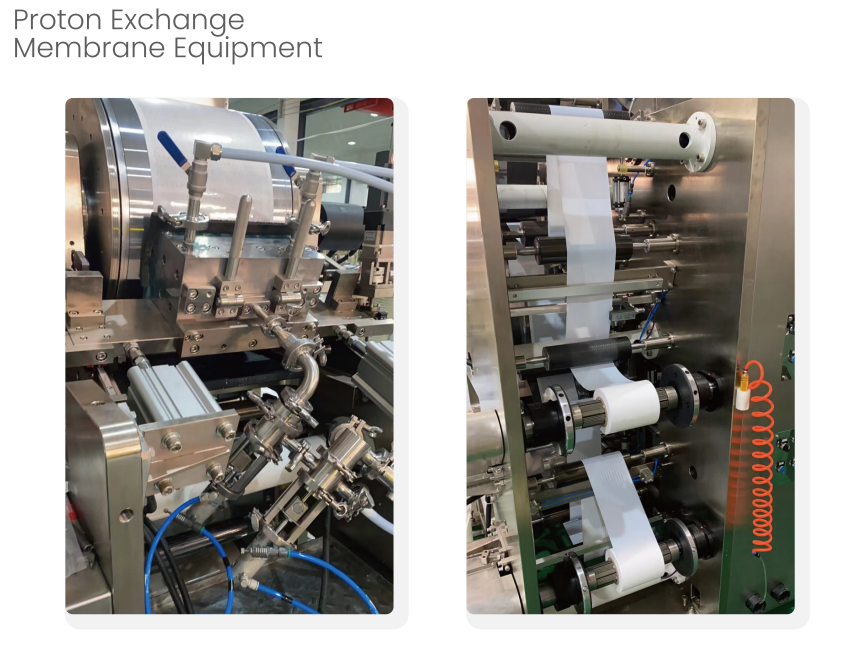

Proton exchange membrane equipment

-

Optical film coating machine

-

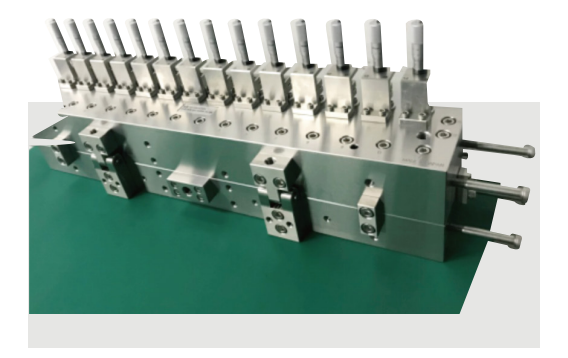

Slot-Die

-

Coating slitting machine

Please refer to the attached image for more detailed product information.

-

Effective Coating width

MAX:1400mm

Coating speed

30-150m/min

Coating size accuracy

≤±0.3mm

-

Mechanical speed

MAX:150-200m/min

Coating roller Circle run-out

≤1.5um(Laser detection)

Tension range/accuracy

30-500N±2N

-

-

-

Single layer closed loop die

Double-layer closed-loop die

MLCC R5/R10 Slot-die

-

LIP Slot-Die

-

-

-

Coating Method

Slit/Micro Gravure

Base material thickness

20-25μm

Tension Range

0-500N

-

Mechanical Speed

1-200m/min

Coating width

300~1600mm

Coating Thickness

15~250μm

-

-

-

Coating Method

Narrow slit continuous extrusion coating

Coating style

Continuous, striped, gap coating

Max. width of substrate

600mm(customizable)

-

Thickness of substrate/composite material

50~80μm

Mechanical speed

15m/min

Coating Speed

1~10m/min(Process determination)

-

-

Perovskite coating machine

Please refer to the attached image for more detailed product information.

-

Coating Method

Slit type casting die head

Substrate size

300mmX400mm/600mmX1200mm

Pedestal

000 level marble platform

-

Substrate loading and unloading method

Automatic loading and unloading

Coating Speed

53s/pcs

Single-side Surface Density Accuracy

Uniformity ≤ 5%

-

-

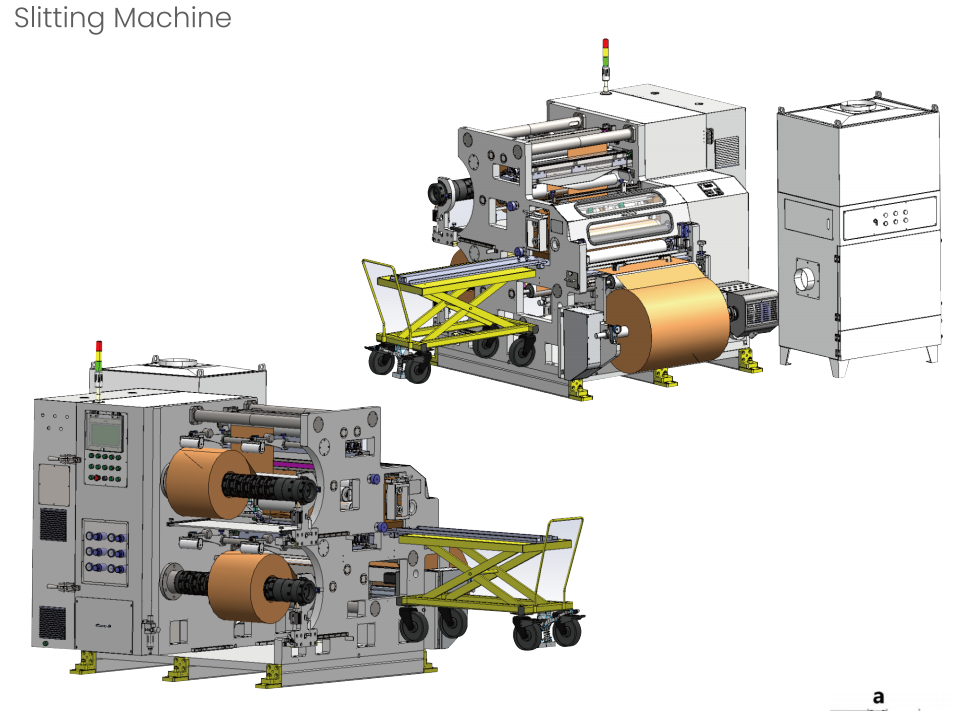

Slitting Machine

1. Suitable for the slitting process of lithium battery separators, electrodes, and ceramic cast film strips.

2. The upper, lower, and circular cutting methods can be switched between each other to adapt to different incoming materials.

3. Optional CCD visual inspection system for online detection of width and defects.

-

Pass rate

99.5%

Mobility

99.8%

Slitting Speed

Electrode 40-100m/min, diaphragm 100-300mm/min

-

Maximum unwinding diameter

800mm

Minimum cutting machine width

35mm

Unwinding correction accuracy

±0.1mm

-

-

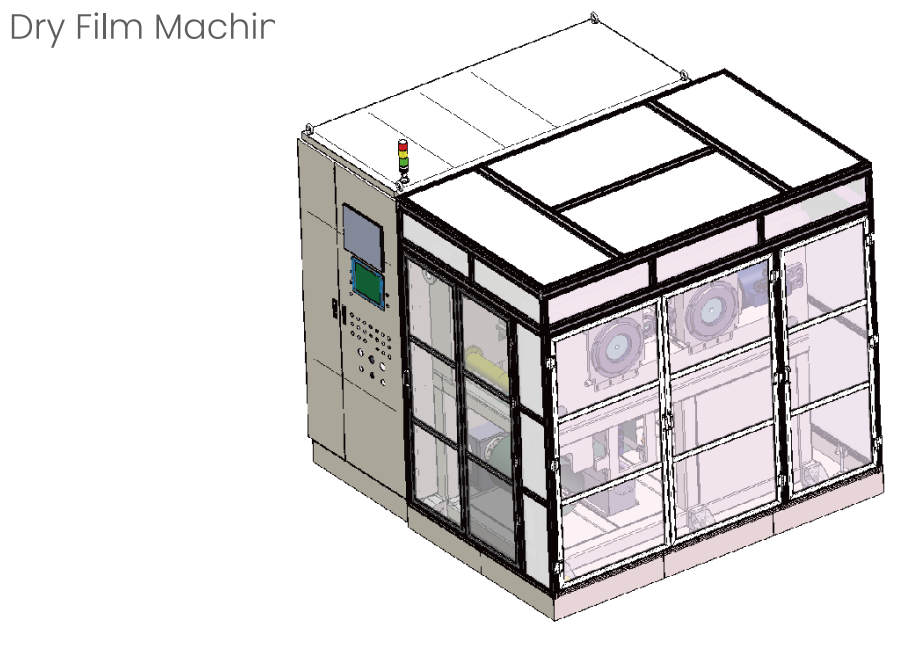

Dry film making machine

1. The width of the powder feeding can be adjusted, which corresponds to different widths.

2. The work roller has hanging materials on the dust removal structure to prevent powder adhesion from affecting the film making accuracy.

3. The working roller can be heated and operated at a temperature of ≤ 160 ℃.

4. Configure a circular knife edge cutting mechanism, with neat edges and an accuracy of ± 0.5mm.

-

Coating Method

Continuous

Electrode manufacturing process

Powder roller pressing

Roll surface width

600m (customizable)

-

Film width

200-500m (adjustable)

Mechanical speed

30m/min

Film thickness

30~200μm(Process determination)

-

-

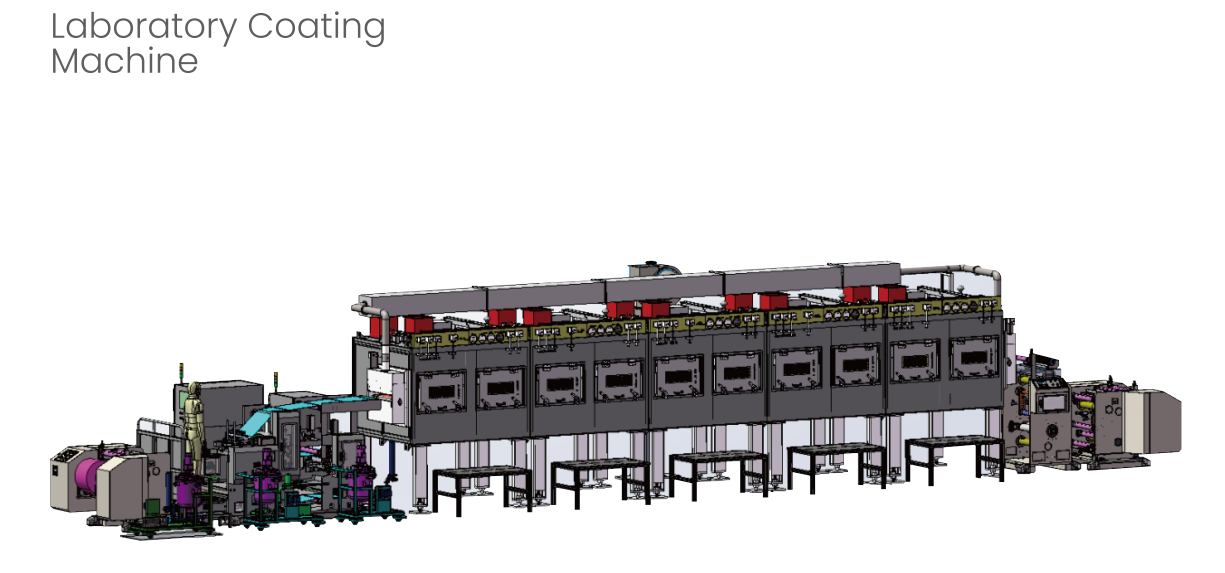

Laboratory coating machine

1. Mainly used for gap coating, it can also be continuously coated according to process requirements, and a micro concave mechanism can be added to achieve one-time completion of various slurries.

2. Compact structure, widely suitable for laboratory coating research.

-

Coating Method

Narrow continuous, gap extrusion coating+micro concave integrated

Effective Coating Width

MAX:450mm

Coating Speed

1-12m/min

-

Coating Size Accuracy

≤0.3mm

Coating Weight Accuracy

±1%

Single-side Coating Thickness Range

5-30mg/sq.cm.

-

-

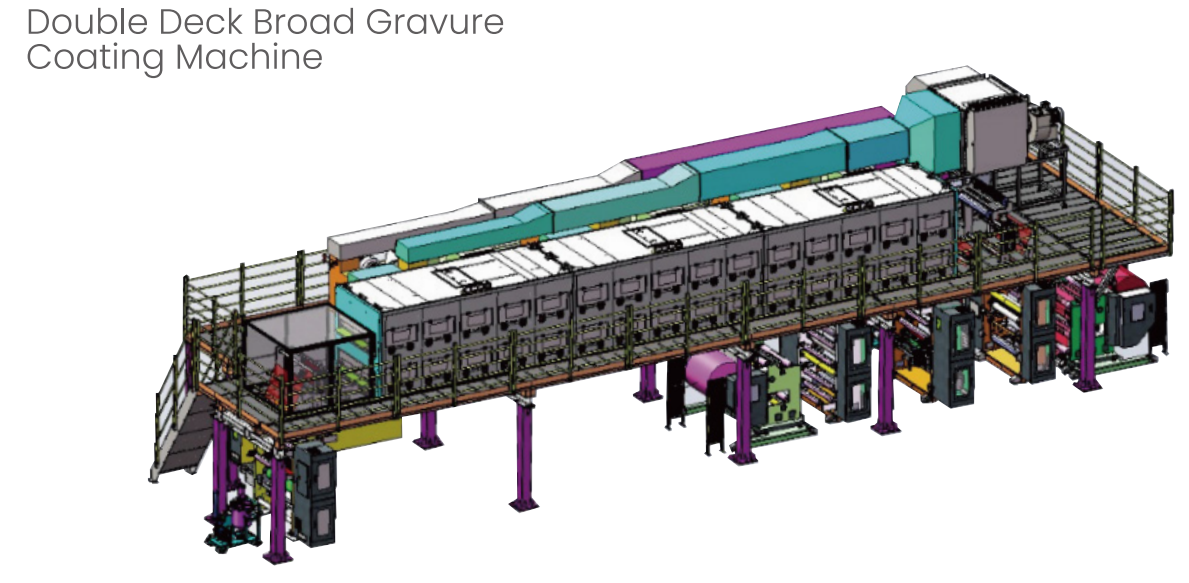

Double layer gravure bottom coating machine

Please refer to the attached image for more detailed product information.

-

Coating Method

Gravure/comma/slit coating

Effective Coating Width

MAX.1400MM

Coating Speed

120m/min

-

Coating Size Accuracy

≤0.3μm

Thickness

±0.3μm

Single-side Coating Thickness Range

1~10μm

-

-

Single layer extrusion coating machine

1. Mainly used for gap coating, but can also be continuously coated according to process requirements.

2. The oven requires higher consistency in wind speed and temperature, with a horizontal and vertical error of less than 5% and an overall error of less than 6%.

3. According to requirements, it can be equipped with dual pump feeding, electrode temperature measurement, air nozzle humidification or overall humidification.

-

Coating Method

Narrow slit continuous extrusion coating

Effective Coating Width

MAX.700MM

Coating Speed

1~40m/min

-

Coating Size Accuracy

≤±0.3mm

Coating Weight Accuracy

±1%

Tension Range

30~500N±2N

-

-

Double Deck High Speed Slot Die Coating Machine

Please download the attached image to view more detailed product information.

-

Coating Method

Narrow slit continuous extrusion coating

Effective coating width

MAX:1400MM

Coating Speed

30-120m/min

-

Coating Size Accuracy

≤±0.3mm

Coating Weight Accuracy

±1%

Tension Range

30-500N±2N

-