-

Double layer high-speed extrusion coating machine

-

Coating and slitting integrated machine

-

Single layer extrusion coating machine

-

Double layer gravure bottom coating machine

-

Laboratory coating machine

-

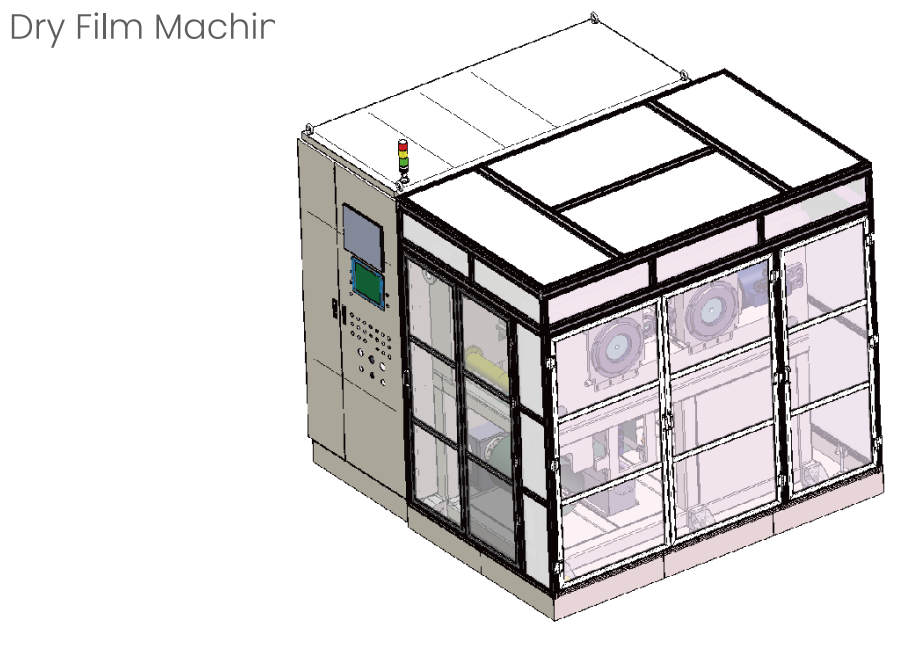

Dry film making machine

-

Slitting machine

-

Perovskite coating machine

-

Proton exchange membrane equipment

-

Optical film coating machine

-

Slot-Die

-

Dry film making machine

1. The width of the powder feeding can be adjusted, which corresponds to different widths.

2. The work roller has hanging materials on the dust removal structure to prevent powder adhesion from affecting the film making accuracy.

3. The working roller can be heated and operated at a temperature of ≤ 160 ℃.

4. Configure a circular knife edge cutting mechanism, with neat edges and an accuracy of ± 0.5mm.

-

Coating Method

Continuous

Electrode manufacturing process

Powder roller pressing

Roll surface width

600m (customizable)

-

Film width

200-500m (adjustable)

Mechanical speed

30m/min

Film thickness

30~200μm(Process determination)

-